Precious die casting is a method of metalworking in which metals are cast into parts using a die. While most parts are made from white metals, the process can also be used to make parts from other metals, including copper and bronze. Precious die casting is a good choice for applications that prioritize light weight and corrosion resistance. There are several reasons why it is the ideal choice for these applications.

Design For Manufacturability, also known as DFM, is a vitally important consideration in die casting. Designers and engineers must be aware of the principles of DFM, especially the importance of proper tooling. A poor design can lead to low-quality parts and high development costs. To avoid this pitfall, it is imperative to know about DFM before designing and purchasing die cast parts. This article explores the fundamentals of DFM.

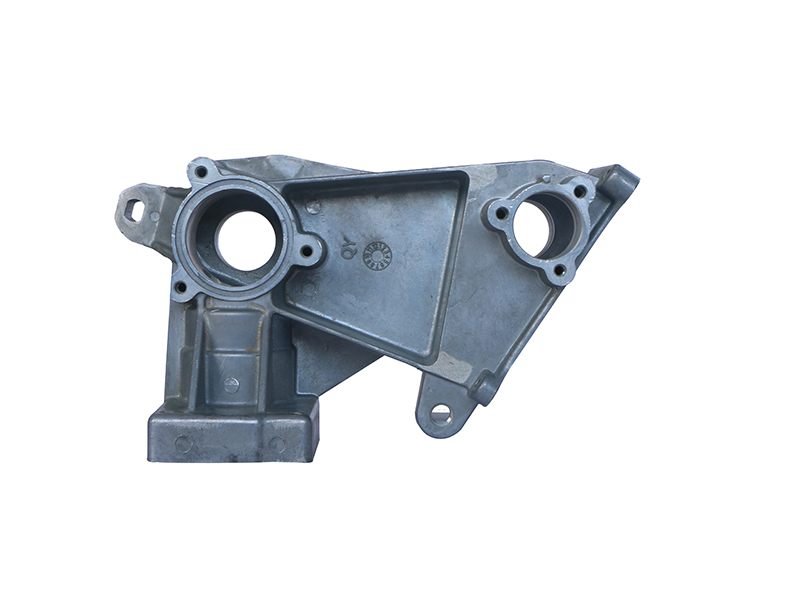

Die casting is a method of manufacturing small-scale parts from metals, such as jewelry. The process begins with a heated chamber that is filled with molten metal. The metal is then forced through a valve into a cavity inside a die. Once the metal has solidified, the two halves of the die separate. This process is able to produce parts that are extremely accurate, even with intricate features.

The process of making metal castings can be an enjoyable and profitable hobby. Once you've mastered the process, you can also turn your creations into bars or other forms for resale. However, this process requires specialized equipment and chemicals to refine the metal. You can make metal castings using an electric furnace, propane furnace, or a microwave melting furnace. The type of equipment you choose will depend on your budget and the type of material you're casting.

English

English 中文简体

中文简体