Throughout the development of the world economy, the mold industry is indispensable in the era of economic prosperity and economic depression. When the economy is developing rapidly, the products sell well, and the molds are naturally required to keep up; and when the economic development is sluggish, the products are not popular, and enterprises try to develop new products, which will also bring strong demand for the molds. Therefore, experts at home and abroad say that the modern mold industry is an enduring industry.

Mold design and manufacturing, sophisticated mold design and manufacturing Mold design and manufacturing is currently in the limelight. It created a whirlwind of mold design in the world. It fills the blank of material research and processing in the original mechanical manufacturing specialty. Mold is important industrial equipment for the production of various industries. It shapes raw materials in a specific form through a certain production method. Mold technology is widely used and has penetrated into every corner of our life.

Modern mold manufacturing is not the same as traditional mold technology. Its main features are as follows:

1. The quality of traditional molds depends on human factors, and the reproduction ability is poor, while the quality of modern molds depends on physical and chemical factors, reproduction ability, and the overall level is easy to control.

2. Traditional mold making is carried out in a serial manner, which is easy to demould in the manufacturing process, with a lot of repetitive work and a long processing cycle, while modern molds are carried out in parallel. The design and manufacture are based on a common mathematical model, which can be used in the overall mold process. Under the guidance of the plan, through public data parallel communication, mutual coordination, sharing of information, less repetitive labor, and a short processing cycle.

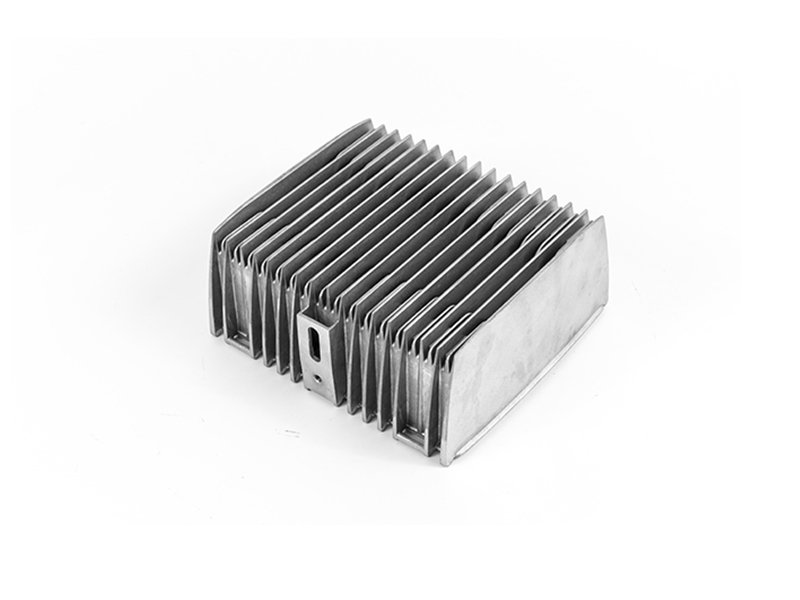

Lighting Accessories-Shell, 400t Press, Lamp Base Accessories

English

English 中文简体

中文简体